Hydro turbine governor knowledge – component of governor and governor type.

What is the main component of an automatic control governor? What is the function of each main component?

- Automatic control governor is mainly composed by measuring element, amplifier, actuators and feedback (or stable) components.

- Measuring element is responsible for measuring the frequency of the unit output power, and compared with frequency given value, when the measured frequency deviates from the given value, signal adjustment.

- Amplifier is responsible for the adjustment signal amplification, and then through the actuators to change the opening of the guide vane, restoring the frequency to the given value.

- The role of the feedback element is for the adjustment system work stable.

- Several types of hydro turbine speed governor?

- According to the different types of velocity measuring components, speed governor can be divided into mechanical type hydraulic governor, electric hydraulic governor and microcomputer governor.

- According to the different flow adjustment methods, it can be divided into two categories governor,single regulation and double adjustable regulation. Such as Francis turbine and axial flow turbine (Propeller turbine), it only change the guide vane opening angle method to adjust flow; The propeller kaplan turbine by altering the guide vane opening and change the runner blade angle to control the flow, this method is called double adjustable regulation; Impulse turbine like turgo turbine and pelton turbine with needle injection changing to control the flow, and also associate with changing deflector to control the flow, it also called double adjustable regulation.

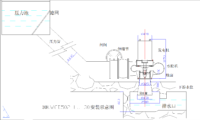

What are the electric hydraulic governor components?

- Electric hydraulic governor consists of two parts, electrical and mechanical hydraulic pressure. Its main components include: permanent magnet generator (also called velocity measuring), frequency measuring circuit, signal amplification circuit, control signal amplification circuit, the electro-hydraulic converter and mechanical hydraulic amplifier device.

- And displacement transducer, buffer circuit, power given with hard feedback loop, power given and frequency given circuit, and opening limits unit, etc

What function of the permanent magnet generator, frequency measuring circuit and the electric-hydraulic converter of electric hydraulic governor?

- Permanent magnet generator is installed on the main shaft, which is to reflect changes in frequency (or speed) of the generator, it supply frequency deviation signal for frequency measuring circuit, and at the same time supply power to the electric circuits of the governor

- Frequency measuring circuit is the use of the resonant circuit composed of capacity cell and inductance components, rather like the role of the mechanical governor pendulum. It will convert the frequency deviation from the permanent magnet generator with the given value to a proportional voltage signal and sent it to the signal integrated circuits to achieve the automatic regulation function of the turbine.

- Electric-hydraulic converter is the connection bridge of the electrical part and mechanical part; it composed of electric displacement part and hydraulic amplification parts. Its role is to convert the electrical output signals into the mechanical displacement signal to achieve a certain operating force