Micro hydro power System Components

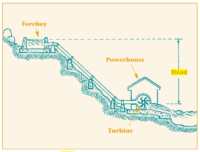

Run-of-the-river microhydropower systems consist of these basic components:

- Water conveyance — channel, pipeline, or pressurized pipeline (penstock) that delivers the water

- Turbine, pump, or waterwheel — transforms the energy of flowing water into rotational energy

- Alternator or generator — transforms the rotational energy into electricity

- Regulator — controls the generator

- Wiring — delivers the electricity.

Commercially available turbines and generators are usually sold as a package. Do-it-yourself systems require careful matching of a generator with the turbine horsepower and speed.

Many systems also use an inverter to convert the low-voltage direct current (DC) electricity produced by the system into 120 or 240 volts of alternating current (AC) electricity. (Alternatively, you can buy household appliances that run on DC electricity.)

Whether a microhydropower system will be grid-connected or stand-alone will determine many of its balance of system components.

For example, some stand-alone systems use batteries to store the electricity generated by the system. However, because hydropower resources tend to be more seasonal in nature than wind or solar resources, batteries may not always be practical for microhydropower systems. If you do use batteries, they should be located as close to the turbine as possible because it is difficult to transmit low-voltage power over long distances.

Micro hydro power System Turbines

Turbines are commonly used today to power micro hydro power systems. The moving water strikes the turbine blades, much like a waterwheel, to spin a shaft. But turbines are more compact in relation to their energy output than waterwheels. They also have fewer gears and require less material for construction.

Only a few companies make microhydropower turbines, and most are high-head turbines. Low-head, low-flow turbines may be difficult to find, and may have to be custom-made.

There are two general types of turbines: impulse turbine and reaction turbine.

Impulse Turbines

Impulse turbines, which have the least complex design, are most commonly used for high-head microhydro systems. They rely on the velocity of water to move the turbine wheel, which is called the runner. The most common types of impulse turbines include the Pelton turbine wheel and the Turgo turbine wheel.

- Pelton turbine wheel — uses the concept of jet force to create energy. Water is funneled into a pressurized pipeline with a narrow nozzle at one end. The water sprays out of the nozzle in a jet, striking the double-cupped buckets attached to the wheel. The impact of the jet spray on the curved buckets creates a force that rotates the wheel at high efficiency rates of 70–90%. Pelton wheel turbines are available in various sizes and operate best under low-flow and high-head conditions. HS Dynamic Energy offer suitable Pelton turbine for customer, check HS Dynamic’s Pelton turbine here

- Turgo turbine impulse wheel — an upgraded version of the Pelton. It uses the same jet spray concept, but the Turgo jet, which is half the size of the Pelton, is angled so that the spray hits three buckets at once. As a result, the Turgo wheel moves twice as fast. It’s also less bulky, needs few or no gears, and has a good reputation for trouble-free operations. The Turgo can operate under low-flow conditions but requires a medium or high head. HS Dynamic Energy offer suitable Turgo turbine for customer, check HS Dynamic’s Turgo turbine here

- Jack Rabbit turbine — a drop-in the creek turbine that can generate power from a stream with as little as 13 inches of water and no head. Output from the Jack Rabbit is a maximum of 100 Watts, so daily output averages 1.5–2.4 kilowatt-hours, depending on your site. Sometimes referred to as the Aquair UW Submersible Hydro Generator.

Reaction Turbines

Reaction turbines, which are highly efficient, depend on pressure rather than velocity to produce energy. All blades of the reaction turbine maintain constant contact with the water. These turbines are often used in large-scale hydropower sites, HS Dynamic design micro hydro turbine and small hydro turbine to meet customer’s need.

Because of their complexity and high cost, reaction turbines aren’t usually used for micro hydro power projects. An exception is the propeller turbine, which comes in many different designs and works much like a boat’s propeller.

Propeller turbines and Tubular turbine have three to six usually fixed blades set at different angles aligned on the runner. The bulb turbine, tubular turbine, and Kaplan turbine, tubular turbine are variations of the propeller turbine. the difference between propeller turbine and Tubular turbine is propeller turbine usually only designed with vertical type, and tubular turbine usually only designed with horizontal type, all these kind of turbine in HS Dynamic can be used for microhydro power project sites. HS Dynamic Energy provide suitable Propeller turbine and Tubular turbine for customer, check HS Dynamic’s Propeller turbine here, check HS Dynamic’s Tubular turbine here

Francis turbines have nine to twenty-one fixed blades set at different angles aligned on the runner. the structure of Francis is similar with Propeller turbine, but more high efficiency range than propeller turbine, which can be used for microhydro project. HS Dynamic Energy provide suitable micro Francis turbine for customer, check HS Dynamic’s Francis turbine here

Pumps and Waterwheels

Conventional pumps can be used as substitutes for hydraulic turbines. When the action of a pump is reversed, it operates like a turbine. Since pumps are mass produced, you’ll find them more readily than turbines. Pumps are also less expensive. For adequate pump performance, however, your microhydropower site must have fairly constant head and flow. Pumps are also less efficient and more prone to damage.

The waterwheel is the oldest hydropower system component. Waterwheels are still available, but they aren’t very practical for generating electricity because of their slow speed and bulky structure.