Function of voltage controller/stabilizer and ELC dump load of micro water turbine plant

Load of water power generator is always changing as user electricity demand. when generator load change, turbine load of water power generator plant change as well. The changing of water turbine load will cause its speed change, so that makes the difference in the speed of water turbine and its rated speed. For example:

- when the propeller turbine with full load and suddenly becomes empty load, its rotating speed could be more than 2 times of the rated speed;

- When turbine load increase, its speed will lower than the rated speed. No matter this speed will exceed or lower than the normal rated speed, it is not good for hydro power plants or power users. Because if the speed of generator running too fast, it will exceed the permissible strength of generator structure.

- On the other hand, users require a stable current and frequency from the micro hydropower station, if the rotation speed of the turbine and generator changing too much, the frequency of electric current will also with larger deviation (normal frequency of the alternating current (ac) are 50 or 60 cycles per second, marked with 50Hz or 60Hz). To avoid the rotation speed of turbine and generator changing too sharp when load reduce or increase, we need a micro hydro turbine automatic speed governor or manual governor to control the turbine output when the load change.

- To make the turbine output can timely meet the change of external load; you must quickly adjust water flow into your micro hydro turbine. Because the generator load changing too fast, so it is hard to control the flow by an artificial method and meet this requirement.

- Therefore, the general hydropower station will equip an automatic mechanical “Governor” to regulate the flow of hydro turbine. But this governor structure is more complex, and the price is expensive, so it is not suitable for micro hydro generator station using governor. Mostly micro water generator will choose water flow control valve to control the rotation speed. And using an electronic load controller (ELC) and dump load to balance the excessive electricity from the generator, this way may ensure a stable current for your electricity demand with competitive price.

It is greater effects of load changing for micro hydropower station than mini hydropower and normal hydro power station.For example:

- 100kw water power generator stations (without governor) have 1kw load changes, changes impact on the whole plant is only 1%, basically does not affect the voltage.

- But, if it is a 5kw micro water power generator station has a 1kw load change, micro power station (no voltage stabilizing controller) voltage change is 120%, the voltage (220 v ×120% = 264 v) will burn your water power generator.

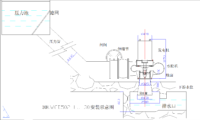

- After years of research now the voltage controller for micro hydro generator from HS Dynamic Energy has been able to solve the problem of voltage stability of the micro water power project. Now the most widely used is resistance energy consumption control. Basic working principle is to use electronic components control voltage, when the load change generator run with high speed, voltage rise, the electronic components will transfer the excessive electricity into another “dump load“(normally a resistive heater), and finally make sure the client with stable voltage and current, so that it can protect your micro hydro generator working safely.

Every off-grid micro hydro turbine generator from HS Dynamic Energy will be equipped with such ELC and Dump load system for our customer, you can go to check now from HS Dynamic Energy’ products.