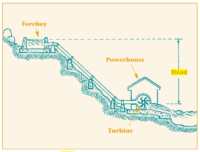

The civil works of home micro hydropower station -Pressure pipe

The pipeline guide the water from forebay to your micro hydropower turbine generator of the power house is called “pipe”. This pipe to bear the pressure of water, especially in the bottom, so the pipes are also called “pressure pipe” or “pressure tube”.

How to choose the pressure pipe of your micro hydropower station

Under a certain water flow condition, the diameter of the pressure pipe is depend on many factors, such as tube flow velocity, water head loss, cost, operation, construction and maintenance etc.

The pipe size of your micro hydropower station is very important, if size is smaller, although the cost is low, but the head loss increase, finally affect the power output; if the pipe diameter is bigger, flow velocity is slow, although the head loss is small, but high cost will trouble you, especially for long pipeline hydropower project. Therefore, the determination of your pile size should take comprehensive analysis of various factors to make rational decision.

Micro hydro power plant pipe diameter selection, generally should be according to the data provided by the micro hydropower turbine manufacturer or provider, here we also offer you with a method to calculate the selection. When the head is not higher than 20 meters, calculation of the pipe flow rate not more than 1.5 m/s. Head in more than 30 meters, the velocity should be around 2 meters; this is our recommendation size of micro hydropower project below 100kw, especially project below 30kw, this is a huge different with normal mini hydropower project and more bigger hydro power project.

Method: velocity V = flow Q /pipe area S

Taking a micro power plant with one kilowatt for example, you can consider to choose plastic pipe, plastic pipe pressure generally is around 3.2 kg, so the head should no more than 32 meters when using this pipe (now lots of PE pipe with PN0.4-6.3, some HDPE with more good performance, so PE pipe is usually used in some micro hydropower project). (10 meters head in 1 cm square area to produce 1 kg pressure) plastic pipe installation should be considered to be buried in soil, in case the sun ultraviolet radiation aging. If system is more than 10kw, you should consider using the steel tube as the pressure pipe (normally with PN2 or more), it can be more suitable no matter the safety and long life using, because you should also consider the water hammer pressure to the pipe.

Choosing steel pipe or plastic pipe and pipe size should accord to the turbine unit and project size.

Pressure pipe construction of your micro hydropower plant

You should ensure that the pipe connection is tight, no leakage, the pipe joint and fixed on the ground should be firm enough, straight tube should be fixed firm on the piers and pier foundation should be strong. The pipe installation sequence is recommended that the bottom-up sequence, it will be a safety construction way.